|

|

Product Name:

Calcined Alumina

:

:

:

|

Calcined alumina

Calcined alumina is generally used in the manufacture of high-grade ceramic shapes, refractories and fused alumina abrasives. It can be compressed to produce a fired density of 3.8 or more. Amazingly, ceramic bodies containing 95% or more alumina are being employed to produce ceramic parts for a wide range industries (fired to 1400C or more). Fabrication methods and glazing vary according to application.

Alumina has a very high melting temperature (about 2000C) and alumina ceramics can maintain up to 90% of their strength above 1100C. They are thus employed in many refractory materials (i.e. Calcium Aluminate Cements have PCEs above cone 35) and used to make parts that must withstand high temperature.

Specificaiton

| FS Polishing series α-AL2O3 micro powder performance indicators |

| Product Band |

Chemical Composition |

Ture Proportion (g/cm3) |

α-AL2O3 |

The average size |

| Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

(%) |

D50,um |

| FS-D01 |

≥99.6 |

≤0.03 |

≤0.02 |

≤0.06 |

≥3.95 |

≥95 |

0.8-1.3 |

| FS-D02 |

≥99.6 |

≤0.03 |

≤0.02 |

≤0.04 |

≥3.96 |

≥95 |

1.5-2.4 |

| FS-D03 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

2.4-3.3 |

| FS-D04 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

3.4-4.2 |

| FS-D05 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

4.3-5.6 |

| FS-D06 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

5.5-6.4 |

| FS-D20 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

18-20 |

| FS-D40 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

35-45 |

| FS-D50 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

46-60 |

| |

| Usage: can be widely used in glass,stainless stell,jewelry,copper,aluminum metal,floor, |

| and varies kind of high-grade furniture of coarse and fine polishing |

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| FS Refractory series α-AL2O3 micro powder performance indicators |

| Product Band |

Chemical Composition |

Ture Proportion (g/cm3) |

α-AL2O3 |

The average |

| (%) |

size |

| Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

|

D50,um |

| FSR-D03 |

≥99 |

≤0.03 |

≤0.02 |

≤0.35 |

≥3.93 |

≥93 |

3.0-3.6 |

| FSR-D04 |

≥99 |

≤0.03 |

≤0.02 |

≤0.35 |

≥3.93 |

≥93 |

3.5-4.3 |

| FSR-D05 |

≥99 |

≤0.03 |

≤0.02 |

≤0.35 |

≥3.93 |

≥93 |

4.5-5.3 |

| FSR-D06 |

≥99 |

≤0.03 |

≤0.02 |

≤0.35 |

≥3.93 |

≥93 |

5.4-6.2 |

| FSR-D07 |

≥99 |

≤0.03 |

≤0.02 |

≤0.35 |

≥3.93 |

≥93 |

6.3-7.2 |

| FSR-D08 |

≥99 |

≤0.03 |

≤0.02 |

≤0.35 |

≥3.93 |

≥93 |

7.8-8.6 |

| FSR-D09 |

≥99 |

≤0.03 |

≤0.02 |

≤0.35 |

≥3.93 |

≥93 |

8.6-9.8 |

| Usage: this productused in the industries of refractory castable, hollow brick,and indus- |

| trial melting furance. |

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| FS Ceramic series α-AL2O3 micro powder performance indicators |

| Product Band |

Chemical Composition |

Ture Proportion |

α-AL2O3 |

The average |

| (g/cm3) |

(%) |

size |

| Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

|

|

D50,um |

| FSC-D01 |

≥99.6 |

≤0.03 |

≤0.02 |

≤0.06 |

≥3.95 |

≥95 |

0.8-1.3 |

| FSC-D02 |

≥99.6 |

≤0.03 |

≤0.02 |

≤0.04 |

≥3.95 |

≥95 |

1.5-2.4 |

| FSC-D03 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.04 |

≥3.96 |

≥96 |

2.5-3.4 |

| FSC-D04 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

3.5-4.3 |

| FSC-D05 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

4.4-5.3 |

| FSC-D06 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

5.6-6.2 |

| FSC-D07 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

6.3-7.2 |

| FSC-D08 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

7.8-8.6 |

| FSC-D09 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

8.5-9.3 |

| FSC-D10 |

≥99.7 |

≤0.02 |

≤0.02 |

≤0.02 |

≥3.96 |

≥96 |

9.2-10.3 |

| Usage: used in the production of high temperature resistant ceramic, corrosion ceramic |

| ,high insulating ceramic, as well as a variety of high-grade civilian sanitary ceramics. |

Advantage

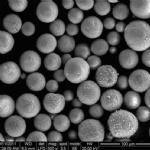

(1) Excellent performance, α-Al2O3 95% min

(2) Using high quality gibbsite-type bauxite

(3) Annual output is 30000 tons

(4) Strict quality mangement system for all products

|

|